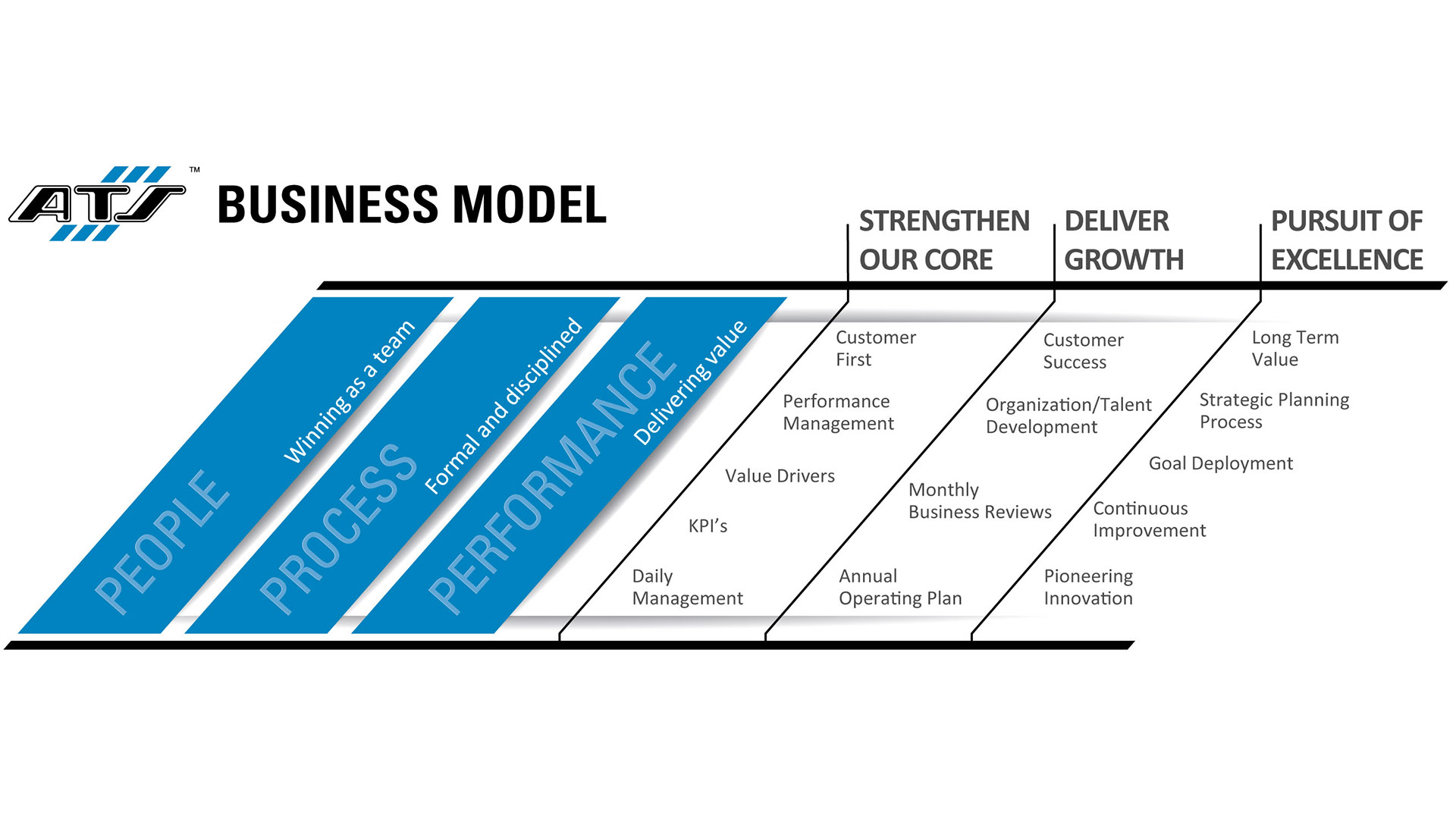

The ATS Business Model has been introduced by ATS Automation in CFT, and it is intended to be a common language to create a widespread culture where it is people who are the starting point. ABM is rooted in Lean methodologies, i.e. a proven and systematic method of searching for waste, problem solving and continuous improvement (kaizen) in procedures in order to ensure that value is created for the customer (performance).

“Not having any problems is the biggest problem of all” Taiici Ohno

Why the Automation Business Model? The customer is at the centre!

The starting point of this model is value, which “can be defined exclusively by the end customer. It only takes on meaning if it is expressed in terms of a product/service capable of satisfying its needs at a given price and at a given moment” (1).

The value we create for the customer is represented by all those features of our product/service that the customer considers necessary and is willing to pay for. The value stream includes all the required activities and actions, both value-added and non-value-added. The latter are referred to as “muda” (waste). Waste includes any activity that absorbs resources but does not create value: defects in products that require reworking, moving and transporting goods from one place to another for no reason, waiting for activities that have not been completed on time upstream. Knowing and recognizing waste is therefore just as important as analyzing it and reducing or eliminating it.

Along with the end customer, it is also crucial to know and collaborate with one’s internal customers (colleagues), ensuring that the entire work stream flows with minimal waste.

How? We measure!

The Plan-Do-Check-Act cycle underlies every method and tool we apply: we measure our objectives and activities with numerical indicators, check for deviations, implement actions to reduce them and check their effectiveness. Proven methods include: problem solving that leads us to identifying the root cause of problems, visual management to quickly highlight problems, process mapping, setting standards for meetings and daily routines.

Continuous improvement with ABM.

No process can be called perfect, as there is always room for improvement. The more we can measure and make problems or non-value added activities visible, the more we can analyze and solve them. One Automation Business Model’s tool that helps us do this is the Kaizen event: a 3-5 day event where a group of people (often from different departments) get together to analyze and eliminate waste, standardize a process and measure its improvement.

It is a shared responsibility!

The ATS Business Model can only work with the involvement and commitment of each and every one of us, because the “real” way to do Lean is strongly linked to behaviour: setting standards, following them every day with discipline, method, and tenacity. Each of us is personally called upon to get to know these tools and integrate them into our activities with the aim of streamlining them.

When the commitment to continuous improvement becomes a working method at all levels of the organization, we are able to see improvements in performance, disciplined processes and see problems as opportunities for improvement. And above all, you are able to truly work as a team, as a group of people who trust each other, exchanging ideas, and willing to give and receive feedback with the common goal of creating value for our internal and external customers.

“It’s easy to have a complicated idea. It’s very hard to have a simple idea”

(1) “Lean Thinking” J.P. Womack, D.T. Jones