Enzymatic inactivation systems

Discover the best way to maintain the product’s initial color, viscosity, and organoleptic characteristics.

This technology preserves the viscosity of the final product, limiting the effects of oxidation and the subsequent use of ascorbic acid to counteract them.

Zenith Chrono

-

Industries:

- Fruits

- Vegetables

-

Min. Capacity:

- 48 tons/day

-

Max Capacity:

- 1,000 tons/day

Benefits

No oxidation thanks to immediate enzyme inactivation and anaerobic environment.

Cold extraction prevents the transfer of unwanted aromas and chemicals to the final product.

No ascorbic acid is needed to avoid first oxidation and there is no product dilution.

Simultaneous processing of different product varieties and ripeness levels without quality loss.

Features

Features

- Immediate enzyme inactivation due to the cold extractor positioned exactly above the hot tank

- Defined residence time ensures no transient heat transfer during processing

- HMI designed to manage all process parameters for efficient control

- Sanitation through CIP system

- Heating of the pulp in a tube-nest exchanger with product recirculation

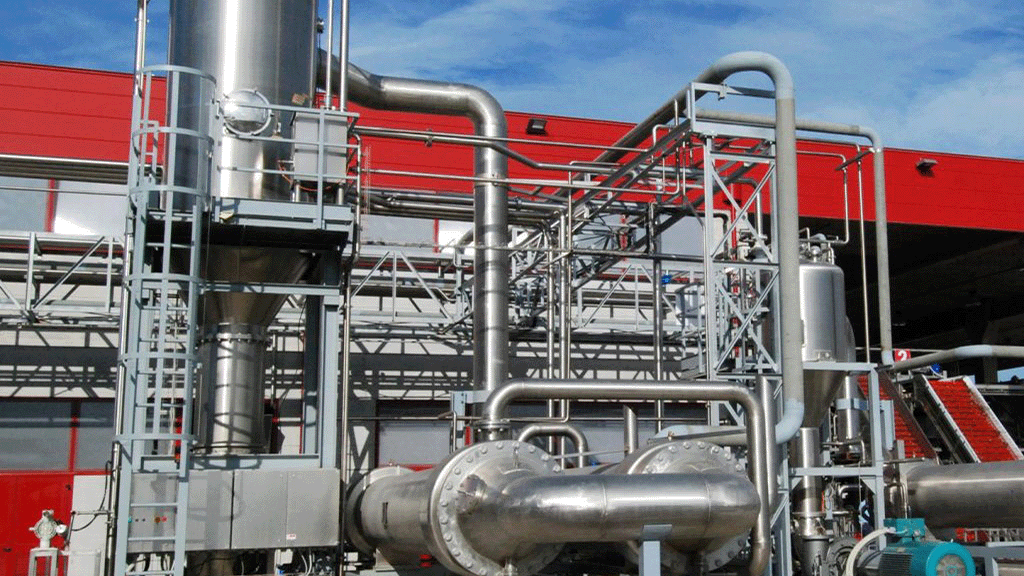

Tube Heat Exchanger

-

Industries:

- Tomato

-

Max Capacity:

- 12,000 tons/day

Benefits

Due to its unique tubular structure, it allows flexible handling of products of varying viscosity.

Maintains flavor and color integrity in the final product.

Tube diameter prevents clogging, ensuring continuous operation.

Cost-effective maintenance for sustainable operations.

Features

Features

- Modular installations allow flexible processing capacity

- Quick transitions between cold break and hot break production

- Achieve low or high-viscosity products with precise temperature control

- Adaptable temperature settings between 55°C to 110°C for versatile product outcomes

ETS (Enzymatic Thermal Shocker)

-

Industries:

- Fruits

- Vegetables

-

Min. Capacity:

- 48 tons/day

-

Max Capacity:

- 1,000 tons/day

Benefits

The indirect heat exchanger ensures higher protection of flavors with no contamination or product dilution.

Accurate and controlled heating without transient heat transfer, optimizing the heat treatment process.

ETS maintains a high viscosity of final products, contributing to product quality and consistency.

The inclusion of a CIP (Cleaning in Place) system allows thorough sanitation.

Features

Features

- Tube-Chest Heating with a product recirculation ratio of 1:5

- Indirect heat exchanger for enhanced quality of the final product

- Specific and controlled residence time

- CIP System Integration

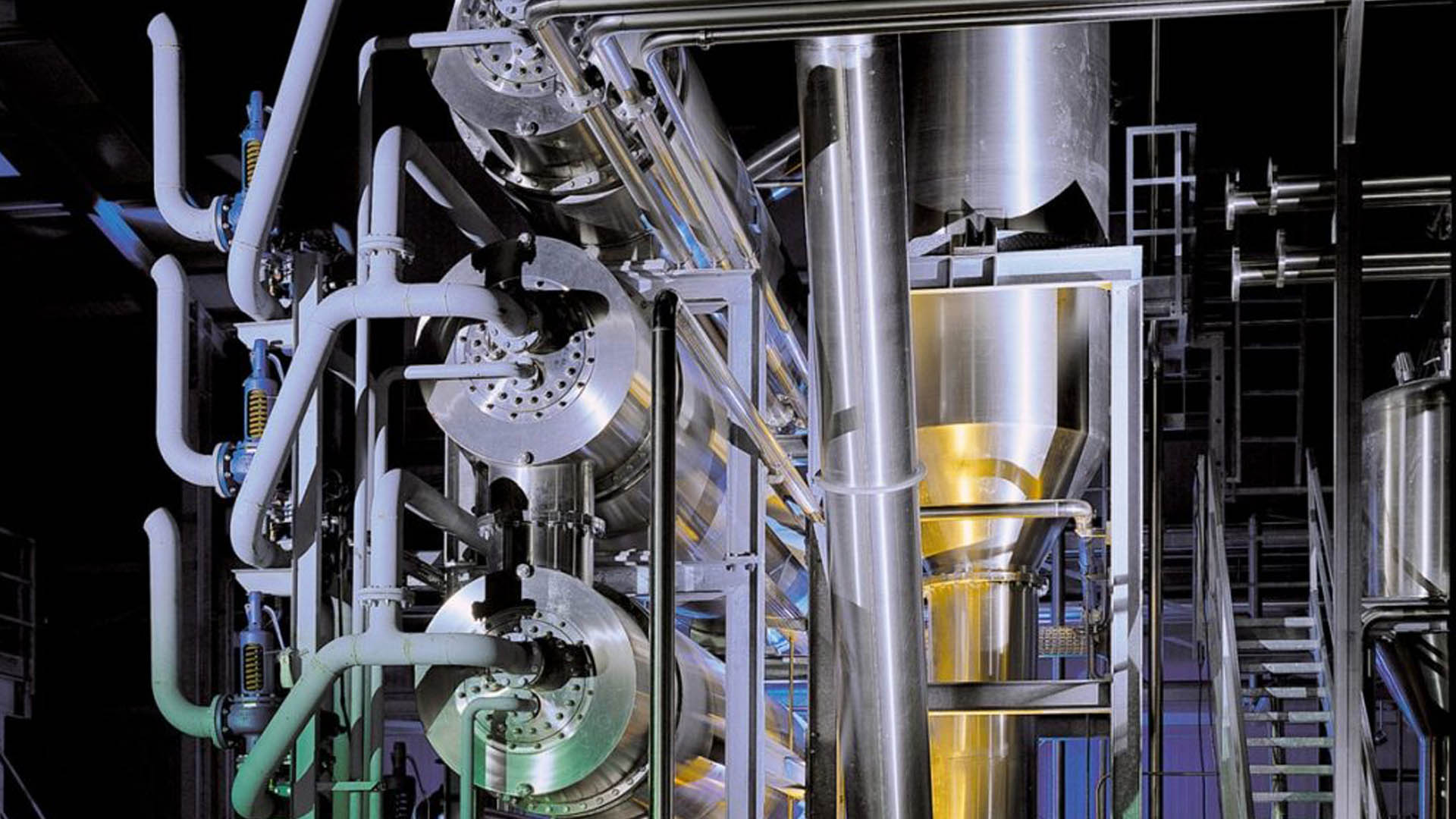

Eldorado Longrun

-

Industries:

- Tomato

-

Max Capacity:

- 12,000 tons/day

Benefits

It operates efficiently for prolonged periods (up to five weeks) without interruption.

Low operational costs due to the system's design and efficiency requiring minimal maintenance.

It preserves organoleptic properties and color, ensuring a final product with very high viscosity and superior quality.

Final product with very high viscosity

Features

Features

- Patented heat exchangers with a unique geometry contribute to the system’s prolonged efficiency

- High recirculation flow-rate, optimizing the enzymatic inactivation process

- Ideal for product enzymatic inactivation between 85°C and 110°C

- Vacuum Process Capability

No machine found. Please use fewer filters.