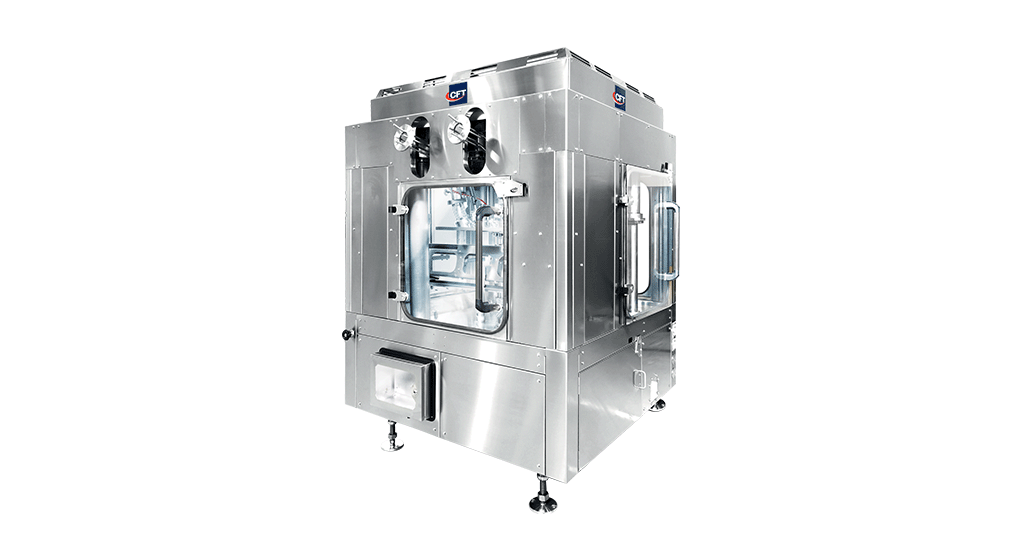

Seamers

Perfect seaming quality, easy format changeover and very simple maintenance.

Our seamers seamlessly integrate with our filling monoblocks, and their reliability is backed by our responsive after-sales service, ensuring timely assistance and genuine spare parts.

Seamer 3000/N

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 30,000 containers/hour

-

Max Capacity:

- 84,000 containers/hour

-

Container:

- Cans

Benefits

100% anti-corrosion steel construction. The machine is entirely

manufactured in stainless steel.

Fully electronic oil lubrication with a recovery and recirculation device for seaming rolls and machine.

Low maintenance costs, 24 hours non-stop operation; quick changeover.

Features

Features

- From 4 to 12 seaming heads

- Diameters: from 246 to 369 mm

- Optional servo-drive technology

- Available configurations: free standing and dual block

Seamer 3000/IB

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 12,000 containers/hour

-

Max Capacity:

- 39,000 containers/hour

-

Container:

- Cans

Benefits

The main parts in the working area are in stainless steel, featuring more resistance and efficient cleaning.

The heads and the rolls are lubricated with oil, with a recovery system to prevent lubricant spillage near the containers.

All the mechanical elements have been designed to guarantee constant performances and long duration.

Features

Features

- From 2 to 6 seaming heads

- Cans diameter: 246 mm

- Optional servo-drive technology

- Available configurations: free standing and dual block

Seamer 3000/E

-

Industries:

- Beverage

-

Max Capacity:

- 4,200 containers/hour

-

Container:

- Cans

Benefits

The machine is entirely manufactured in stainless steel, guaranteeing a high level of sanitation.

Quick changeover features and use of no-maintenance (NOMA) rolls.

Electronic cams, recipes upload and seaming turns control from HMI.

Features

Features

- 1 seaming head

- Cans diameter range: 50-90 mm – Cans height range: 70-210 mm

Seamer 2000/S

-

Industries:

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 9,500 containers/hour

-

Max Capacity:

- 13,500 containers/hour

-

Container:

- Cans

Benefits

Simple frame made of cast iron with stainless steel coat, for a good quality and a long machine life cycle.

Automatic greasing system for seaming rolls and machine lubrication.

Specifically designed to make all phases of the size change-over very quick and simple.

Features

Features

- From 3 to 4 seaming heads

- Grease lubrication system

- Not rotating cans

- Designed for big sizes

Seamer 2000/L

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 6,000 containers/hour

-

Max Capacity:

- 36,000 containers/hour

-

Container:

- Cans

Benefits

Simple frame made of cast iron with stainless steel coat, for a good quality and a long machine life cycle.

Automatic greasing system for seaming rolls and machine lubrication.

Specifically designed to make all phases of the size change-over very quick and simple.

Features

Features

- From 2 to 6 seaming heads

- Grease lubrication system

- Medium speed configuration

Vacuum Seamer ASV8

-

Industries:

- Other Foods

- Tomato

- Vegetables

-

Max Capacity:

- 36,000 containers/hour

-

Container:

- Cans

Benefits

Particularly

recommended to preserve the nutritional values of the product.

Constant and very high vacuum reached inside the can (higher than 70 cm/Hg).

Automatic greasing system for seaming rolls and machine lubrication.

Features

Features

- 8 seaming heads

- Cans diameter: 370 mm

- Optional servo-drive technology

- Available configurations: free standing and dual block

No machine found. Please use fewer filters.