A Successful Project for the Middle East

Between spring 2021 and the end of 2022, we designed and installed two sauce preparation plants for a major client in the Middle East.

The collaboration with the client

Our collaboration with the client began in 2017, and over the years, we have been involved in numerous projects concerning the processing and packaging of various products, including oil, tomato paste, ketchup, and mayonnaise.

The most recent project we completed involved the construction of two separate plants dedicated to the preparation and production of ketchup and mayonnaise.

Both sauce preparation lines have a capacity of 4t/h for ketchup and 4t/h for mayonnaise: the first plant can process these sauces simultaneously, while the second is configured to handle ketchup and mayonnaise alternately.

CFT solution: ketchup and mayonnaise preparation lines

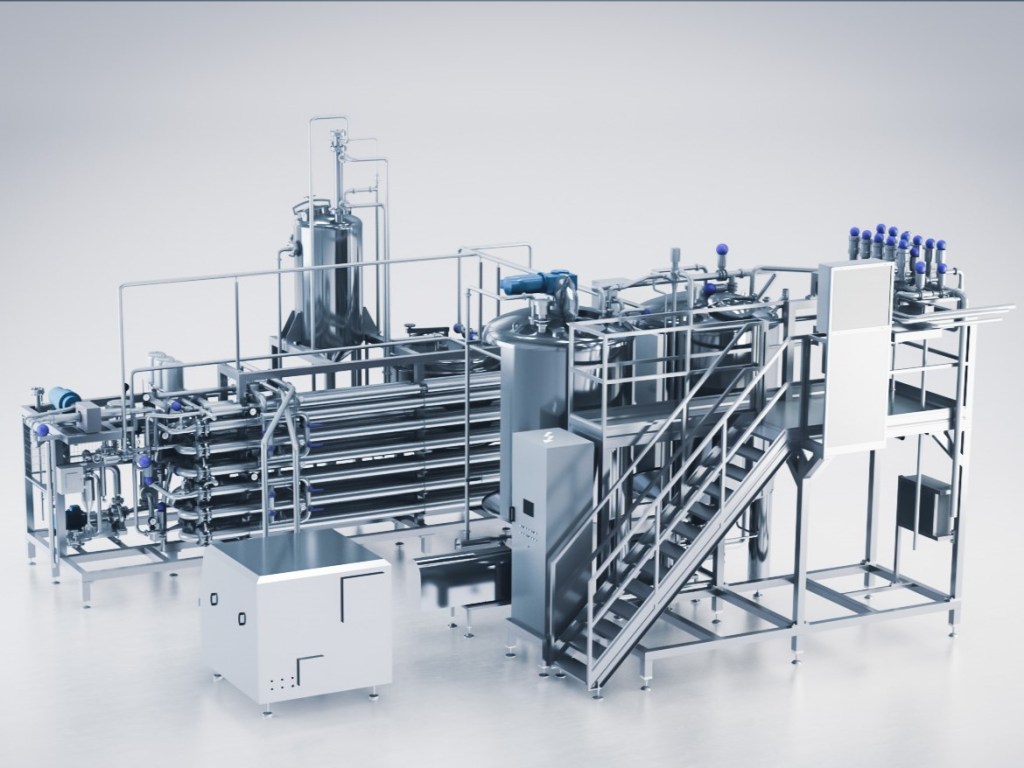

The ketchup and mayonnaise preparation lines we built for the client have a similar structure, with the main sections composed of:

- Storage, preparation, and ingredient dosing section, including powder dissolution and dosing units, emptying systems, and storage tanks.

- Mixing and preparation section for mayonnaise and ketchup, featuring our Jupiter cooker, present in just one of the lines.

- Sterilization section for Ketchup – Olimpic TC- S/PK, with the possibility of working with two configurations (homogenizer in aseptic zone or non-aseptic homogenizer).

- Centralized and automatic CIP system for line washing.

- “RC-View” control software for sauce preparation, a supervision system that allows the creation of recipes and different sequences, visualization of all variables, archiving of all process data, and processing of all necessary data for the best management of the plant.

Competitive Advantages of Our Solution

Our offering includes advanced hygienic solutions and a highly efficient Clean-In-Place (CIP) washing system that meets the highest standards. This ensures an impeccable production environment, where hygiene is at the forefront of our priorities.

Our production line is characterized by considerable flexibility, guaranteeing the highest quality for all processed products. This versatility allows us to adapt to specific customer needs and maintain excellence standards in every production phase.

Additionally, we use advanced control software, RC-View, equipped with an intuitive interface. This software offers a wide and comprehensive range of functionalities, including the creation of customized recipes and sequences. This enables optimal management of the production process, allowing for rapid adaptation to customer-required variations or customizations.

Future Perspectives and Market Trends

Following the excellent results achieved with the sauce preparation lines, the client has entrusted us with a new project. We are currently proceeding with the shipping and future installation of a line dedicated to filling buckets containing mayonnaise and ketchup. The global sauce market, valued at $55.20 billion in 2022, is projected to reach $84.71 billion by 2030, with a CAGR of 5.5% during the forecast period from 2023 to 2030. Ketchup remains the dominant segment of this market, thanks to its versatility and widespread consumption, attracting a broad range of consumers. This tomato-based sauce is not only a table condiment but also a fundamental ingredient for sauces, dips, and various dishes, making it a staple food in many households.

Source: Data Bridge Market Research